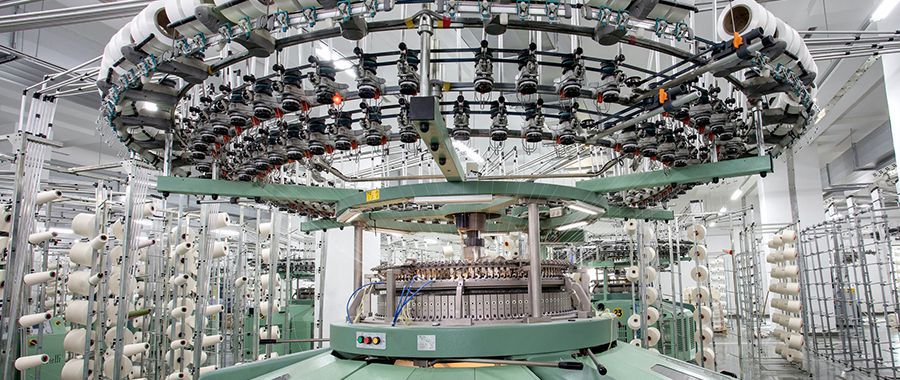

Belting for Textile and Yarn Manufacturing

In the textile industry, yarn spinning, twisting, winding and finishing are processes that need tangential belts. A tangential belt drives a plurality of spindles of a spinning or twisting machine, which means that the tangential belts are critical in high-performance operation of spindles under high speed. Spindle tapes are often used as an alternative to tangential belts in ring spinning machines to drive spindles.

Dongji offers belting solutions for your yarn and textile production needs from fiber preparation through to yarn spinning and finishing applications.

Dongji's High-performance Flexproof Power Transmission Belt

Features

- Good resilience, improved shock absorption;

- High power transmission efficiency of the belt cross-section;

- Superior longitudinal flexibility, high abrasion resistance and high grip;

- Not affected by climate change, difficult to break;

- Outstanding reversed bending;

- Precise Flexproof joining, smooth belt surface;

Applications

- Double twisting machine

- Spinning machine

- Open-end spinning machine

- Yarn covering machine

- Carding machine

- Draw texturing machine

- Draw frame

- Combing machine

- And more

Dongji's Flexproof Energy-Saving Spindle Tape

Features

- Permanent antistatic property;

- Belt coating in contact with spindle is made of wear-resistant polyurethane;

- PU impregnated wear-resistant fabric on spindle side surface;

- Flexproof joining method, simple and fast to join without adding adhesive;

Applications

- Spinning machine

- Twisting machine

- Double twisting machine

- And more

Tangential Belt

RER20/22EF - TC

- Material: 2 plies of nitrile butadiene rubber (NBR), 1 ply of polyethylene terephthalate (PET)

- Construction: NBR / PET / NBR

- Thickness: 2.2mm (±0.1mm)

- Color: light green / black

RER35/30ER - TC

- Material: 2 plies of nitrile butadiene rubber (NBR), 1 ply of polyethylene terephthalate (PET)

- Construction: NBR / PET / NBR

- Thickness: 3.0mm (±0.1mm)

- Color: light green / black

Dongji owns professional large-scale manufacturing plant and warehouse for polyurethane flat belts and polyamide power transmission belts. Ingenious manufacturing to the highest international standards has been central to Dongji's strategy since its inception. We are the first domestic industrial belt manufacturer using thermoplastic polyurethane (TPU) and nanomaterials to produce high-performance conveyor belts. The features of produced flat belts include energy saving, burr-free edge, antistatic property, high conductivity and good resilience, as well as outstanding resistance to abrasion, bending, chemicals, oil, and high or low temperatures, enabling the industrial belts versatile enough to accommodate the individual production process of diverse automatic manufacturing equipment.